Home > Products > Transparent PCB and Transparent FPC > Transparent FR-4PCB,FR-4, TG130 material,PI transparent flexible board FPC

Transparent FR-4PCB,FR-4, TG130 material,PI transparent flexible board FPC

- China Shenzhen,Shekou

- T/T L/C D/P

- 25 days

You May Like

-

1.60mm transparent FR-4PCB,Ultra thin transparent FR-4PCB

-

blind buried hole HDI flexible FPC,4-layer flexible FPC

-

12 layers of flexible multi-layer,soft hard combined FPC,Mobile phone motherboard, touch screen

-

Aviation Bluetooth Glasses,16 layers HDI 4th order

-

PET transparent single-layer double-layer flexible FPC,Single layer PET material flexible flexible board FPC

-

Apple iPhone 12 layer arbitrary soft hard combination HDIFPC

Product Details

| Material | Aluminum Covered Copper Foil Layer | Type | Combining Rigid Circuit Board | |

| Application | Communication | Brand | China Chaosheng PCB | |

| Flame Retardant Properties | V0 | Dielectric | FR-4 | |

| Insulation Materials | Organic Resin | Processing Technology | Delay Pressure Foil | |

| Mechanical Rigid | Rigid | Base Material | Copper | |

| Transport Package | Vacuum packaging+separated white paper+moisture-proof beads | Specification | 250*1200mm | |

| Trademark | N0 | Origin | Shenzhen Shekou, China |

Product Description

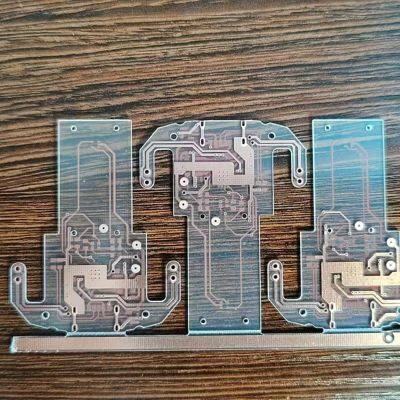

Transparent FR-4PCB

Product Name: Transparent FR-4PCB

Board: FR-4, TG130 material

Number of floors: 2

Minimum line width/spacing: 12/12mil

Finished product size: 250x1200mm

Surface technology: Sinking gold

Copper thickness: 35um

Plate thickness: 1.60mm

Minimum hole: 0.50mm

Features: Transparency meets 85-95% and can withstand normal temperatures of 220-240 degrees Celsius

Usage: Large size, LED transparent screen, display frequency, LED glass screen, etc

Detailed Introduction to Transparent FR-4 Multilayer PCB

Material characteristics

High transparency: Using special transparent FR-4 material, the transparency can reach 85% -92%, which can clearly display the internal circuit layout and component arrangement, bringing unique visual effects to product design.

Good electrical performance: Similar to ordinary FR-4 material, it has excellent electrical insulation performance, which can effectively prevent current leakage and electromagnetic interference, ensuring stable operation of PCB in complex electrical environments.

High mechanical strength: The glass fiber reinforced epoxy resin laminated board endows the transparent FR-4 multi-layer PCB with good mechanical strength, enabling it to withstand certain external impacts and vibrations, and is not easily deformed or damaged, making it suitable for various application scenarios.

Heat resistance: The heat resistance temperature range is usually between 130 ℃ and 180 ℃, which can maintain the stability of its structure and performance in higher temperature environments and adapt to different working environments.

Flame retardancy: As a flame-retardant material, FR-4 has flame-retardant properties and can self extinguish when burned, improving the safety of PCB use and complying with relevant safety standards 2.

manufacturing process

High precision etching: Through high-precision exposure and etching processes, the transparent conductive layer is precisely processed to ensure that the line width and spacing accuracy of the circuit pattern meet the design requirements, usually up to 3/3mil or even smaller, ensuring the accuracy and consistency of the circuit.

Laminated process: Advanced laminating technology is one of the key steps in manufacturing transparent FR-4 multilayer PCBs, which requires ensuring tight bonding between layers to avoid problems such as bubbles and stress concentration. At the same time, it is required that the alignment error between layers be less than 10 μ m to ensure the performance and reliability of the multilayer board.

Surface treatment: According to different application requirements, various surface treatment methods are provided, such as OSP (organic solder mask), gold deposition, tin spraying, etc., which can improve the oxidation resistance, solderability, and wear resistance of the circuit board surface.

Application Area 1

Intelligent display: such as transparent display screens, smart glass, etc. The transparent FR-4 multi-layer PCB provides a transparent circuit solution for display devices, making the display effect more unique and beautiful, while also achieving higher integration and functionality.

Automotive electronics: Used for intelligent instrument panels, head up displays, and other components in cars, which can enhance the driving experience and bring more innovative space to car interior design, making the electronic devices in the car more integrated with the overall interior style.

High end consumer electronics: In products such as smartphones, tablets, wearable devices, etc., transparent FR-4 multi-layer PCB can provide more creativity for product design, showcase the technological and exquisite sense of the product, and meet consumers' needs for personalization and aesthetics.

Medical equipment: In the fields of medical imaging equipment, medical monitoring instruments, etc., transparent PCBs can provide clearer image transmission and signal processing, which helps doctors to diagnose and treat more accurately, and also facilitates equipment maintenance and repair.

| Transparent FR- 4 material layers | 1-2layer | 1-2layer | 1-8layer | |

| Transparent FR-4 minimum hole | 0.35mm | 0.35mm | 0.35mm | |

| Transparent FR-4 minimum line width and spacing | 4/4Mil | 4/4Mil | 3.5/3.5Mil | |

| Transparent FR- 4 maximum size | 23.63*47.25″ | 23.63*47.25 ″ | 23.63*47.25 ″ | |

| Number of tempered glass base layers | 1-2layer | 1-2layer | 1-2layer | |

| Minimum line width and spacing of glass | 4/4Mil | 4/4Mil | 3.5/3.5Mil | |

| The smallest hole in glass | 0.35mm | 0.35mm | 0.35mm | |

| Maximum size of glass | 23.63*47.25″ | 23.63*47.25 ″ | 23.63*47.25 ″ | |

| Number of layers of transparent PETmaterial | 1-2layer | 1-2layer | 1-2layer | |

| Maximum size of transparent PET | 19.68 ″*7874" | 19.68 ″*7874" | 19.68 ″*7874" | |

The company's main product types | Halogen free materials, high TG materials, high-frequency materials, high-speed materials, metal materials, glass materials, embedded materials, transparent FR- 4 materials, high thermal conductivity metals, high thermal conductivity aluminum substrates, environmentally friendly circuit boards, BT materials, ABF materials, and other imported materials, DU busbars, iron-based and metal based (core) mixed pressure plates, embedded buried copper, buried resistors, buried capacitors, buried ceramic bead plates, buried ceramics, ceramic mixed pressure plates, multi-layer ceramics, ultra-thin BT plates, ultra-thin PCBs, ultra-thin PCBs, multi-layer aluminum substrates, multi-layer ceramic plates, multi-layer ultra-thin HDI、 High frequency mixed voltage, differential impedance board, thick copper plate, gold-plated plate, high and low copper, high and low copper, high carbon resistance, transparent multilayer, glass plate, HDI arbitrary order (cross blind buried) Anylayer, flexible double-sided, flexible multilayer, soft hard combination HDI, roll to roll FPC, ultra long size, ultra large size board (single, double, multi-layer) PCB production and product design, product development, software development, etc | |||

| Main material | Rogers, Taikoni, Yaron, Mitsui, Isola, 3M, Taiyao, Taiguang, Tenghui, Shengyi,Lianmao, Nanya, Doosan, DuPont, Taihong, Hongren, Xinyang, Nippon Steel, Teflon,Yasen, Panasonic, RCC, Mitsui, Mitsubishi, Yingye, 3M, Kyocera, Jiuhao, Zhongci,Huaqing, Aishengda, Sliton, Kaichangde, Tongxin, Beige, Yalong, Taikoni,Hitachi, Laird System, etc | |||

Main material categories | Halogen-free、halogenated、 high thermal conductivity, high TG135 、TG140、 TG150、 TG170、TG180、TG240、TG320 | |||

| Build-up Material | FR-4 ,TG150,TG70,TG180 | |||

| Conventional plate thickness (mm) | Min.1-2L(mm) | 0.10mm | 0.10-12.0mm | 0.10-18.0mm |

| Min.4-10L(mm) | 0.35mm | 0.35mm~10.0mm | 0.35-18.0mm | |

| Min.12L(mm) | 0.43 | 0.38~10.0mm | 0.38~18.0mm | |

| Min.16L(mm) | 0.53 | 0.45~10.0mm | 0.45~18.0mm | |

| Min.18L(mm) | 0.63 | 0.51~10.0mm | 0.51~18.0mm | |

| Min.52L(mm) | 0.8 | 0.65~10.0mm | 0.65~18.0mm | |

| MAX(mm) | 3.5 | 12.0mm | 18.0mm | |

Company Profile

Company Profile The development history of Chaosheng Group shows a typical trajectory from its establishment to growth into a leader in the printed circuit board industry. A brief overview of Chaosheng Group, its subsidiaries, and specialty products: History and Background of Chaosheng Company: Chaosheng Group was founded in 1968, originating from Japan, under the name Chaosheng Technology Japan Kawasaki Co., Ltd. In 2012, the company implemented a shareholding reform, marking a shift towards more modern and standardized management. As a Sino Japanese Hong Kong joint venture, Chaosheng Group holds an important position in the Chinese circuit board manufacturing industry. Global factory distribution Zhejiang Kunying Electronic Technology Co., Ltd. (formerly renamed after the merger of Taiwan Kunying Electronics) was established in 2001, increasing the production and technical capabilities of Chaosheng Group in the field of circuit boards. Mainly focusing on high-end precision flexible circuit boards. Shenzhen Chaosheng Electronic Technology Co., Ltd. and Shenzhen Guangrui New Electronics Co., Ltd. (formerly known as Shenzhen Mingze Electronics Co., Ltd.) were established in 1993 and 2008 respectively, further expanding Chaosheng Group's layout in the Chinese market. We mainly provide supporting processing factories for customers in product design, software development, product research and development, and SMT surface mount processing. Chaosheng Group has multiple sales networks worldwide, covering France, the United Kingdom, Germany, Japan, Europe, Switzerland, Africa, North America, Austria, Taiwan, Hong Kong and other countries and regions, showcasing its global influence. Product Features and Applications: Widely used products: communication equipment, communication instruments, optical communication, infinite terminals, new energy, intelligent systems, medical devices, detection systems, aviation, aerospace, military, drones, robots, AI technology, 5G equipment, 5G communication, optical products, LED、 The high-tech fields such as communication, automotive, and home electronics reflect the technological strength and market insight of Chaosheng Group. Main materials: halogen-free materials FR-4, Polyimide PI materials, high TG materials, high-frequency materials, high-speed materials, metal materials, glass materials, embedded materials, transparent FR-4 materials, heat dissipation materials, embedded materials, high thermal conductivity metals, high thermal conductivity aluminum substrates, environmentally friendly circuit boards, BT materials, ABF materials, etc. Product structure: Metal based mixed pressure plate, embedded copper, buried resistance, buried capacitance, buried ceramic bead plate, buried ceramic, ceramic mixed pressure, multi-layer ceramic, BT board, ultra thick PCB, multi-layer aluminum substrate, high-frequency mixed pressure, impedance board, thick copper plate, thick gold plated board, high and low copper, high carbon resistance, transparent FR-4 multi-layer, glass plate Anylayer、 Single, double, multi-layer, soft and hard combination HDI, roll to roll FPC, ultra long and ultra large size boards, PCB production and product design and development, software development and SMT, PCBA and other integrated production factories The annual output value of Chaosheng Group exceeds 100 billion yuan, with the annual output value of printed circuit boards reaching over 65 billion yuan, demonstrating its strong production capacity and market competitiveness. With the continuous advancement of technology and changes in the market, Chaosheng Group needs to continue to pay attention to the dynamics of new technologies, products, and markets, strengthen research and development investment and innovation capabilities, in order to maintain its competitive advantage and industry position.

Contact Us

- Shenzhen Chaosheng Electronic Technology Co., Ltd.

- Contact nameMank.Li Chat Now

- Phone86-0755-89586738

- AddressAilian community shigangxu rd industrial zone, Shenzhen, Guangdong

Product Categories

New Products

-

iPhone 12 layer arbitrary soft hard combination HDI Flexible FPC,multi-layer flexible HDIFPC,

-

6L high-speed rail car high-voltage soft hard combination FPC

-

2-layer SG card, SD card, thick goldPCB,Multi layer ultra-thin PCB

-

2-layer thin plate thick gold PCB,Ultra thin thick gold SG card gold finger PCB

-

2-layer ultra-thin ultra large size PCB,Ultra thin multi-layer PCB

-

2-layer thin plate+thick metal+high carbon resistancePCB,Micro motor ultra-thin high carbon resistance PCB

-

4-layer 15OZ thick copper+copper bar+copper based charging pile PCB,High thermal conductivity copper based+8W adhesive PCB

-

4-layer high-voltage thermoelectric separation thick copper aluminum substrate

-

2layer high-voltage thermoelectric separation thick copper aluminum substratePCB

-

2-layer thermoelectric separation high current multi-layer aluminum based PCB

-

4 thick copper high thermal conductivity thermoelectric separation aluminum basePCB

-

4-layer thermoelectric separation high current multi-layer aluminum based PCB,Thermoelectric separation aluminum based circuit board PCB

-

6layers of copper with a thickness of 210um, thermoelectric separation aluminum basedPCB

-

4-layer recessed thick copper charging pile PCB,Bent copper electrolytic PCB

-

Bend type recessed copper based PCB,Inward bending copper based PCB

-

Inlaid thick copper bent PCB,Bent copper electrolytic PCB

-

False 2-layer recessed thick copper bent PCB

-

2-layer false double-layer recessed thick copper bent PCB,Inward bending copper based PCB

-

12 layers, 2nd order high-frequency mixed voltage, 2nd step PCB

-

16 layers, 3rd order high-frequency mixed voltage, 6 step PCB

-

8 layers, 3rd order HDI high-frequency mixed pressure buried copper PCB,8th layer 3rd order optical module buried resistance PCB

-

8 layers, 2nd order HDI high-frequency mixed voltage buried resistance PCB,8-layer 2nd order optical module embedded gold finger PCB

-

8 layers, 3rd order HDI high-frequency mixed pressure buried capacitive gold finger PCB

-

8 layers of HDI high-frequency mixed pressure buried capacitor+buried copper block+gold finger PCB

Popular Searches

- multilaye pcb manufacture

- mcpcb

- Led Aluminum Pcb

- Led Light Pcb

- Led Lighting Pcb

- single side led pcb

- Aluminum Led Pcb Board

- Designator Mount

- led panel pcb

- led strip pcb

- led aluminium pcb

- led bulb pcb

- led mcpcb

- pcb board single side

- ip camera pcb board

- game controller pcb

- single side pcb

- taiyo

- metal enclosure pcb

- pcb holding

- box mod clone

- etching machine circuit board

- electronics cards

- single-sided pcb

- a c control pcb board

- ac pcb board

- aluminum base circuit

- aluminum led pcb

- rigid led pcb

- Based Board

Find Similar Products By Category

- Electrical & Electronics > Circuit Board > Multilayer PCB

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Mank.Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Mank.Li

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile